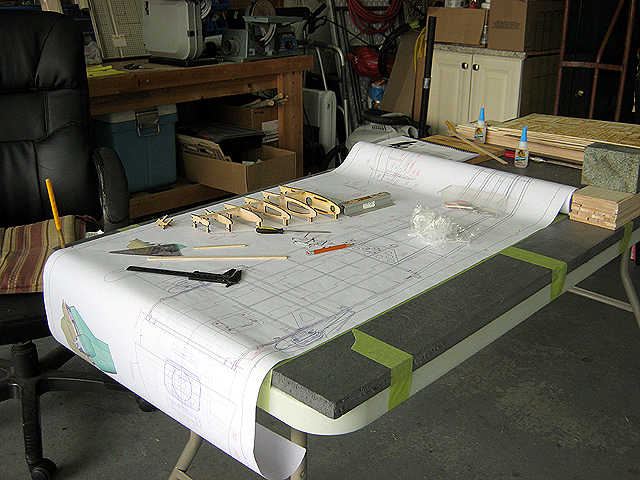

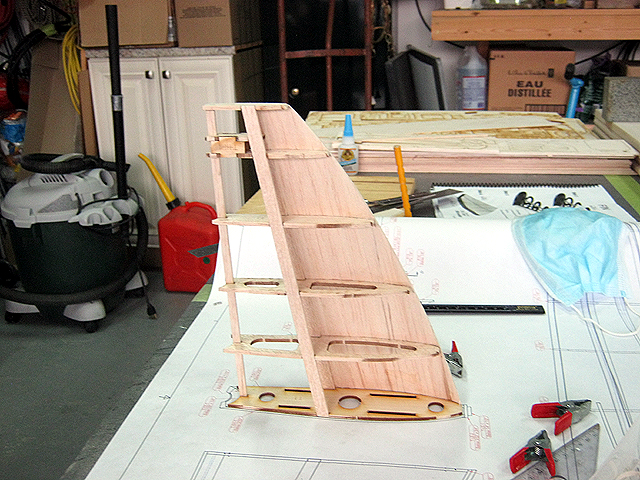

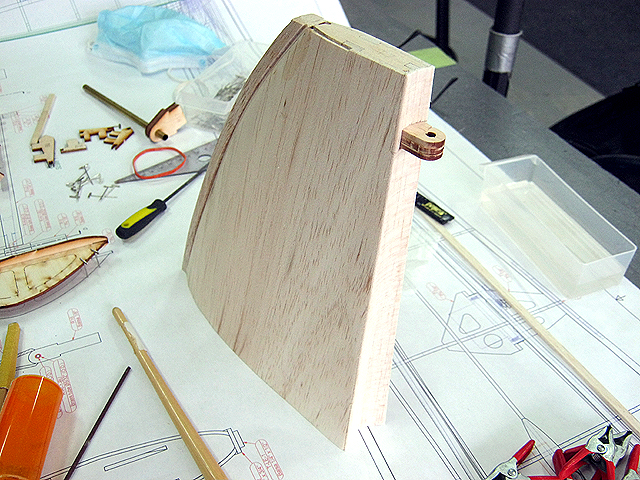

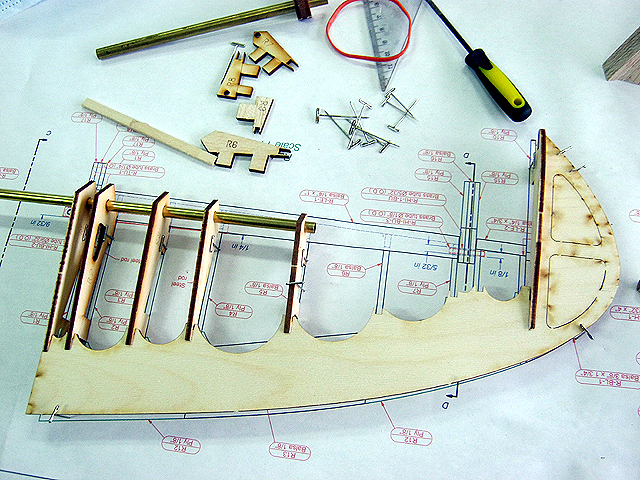

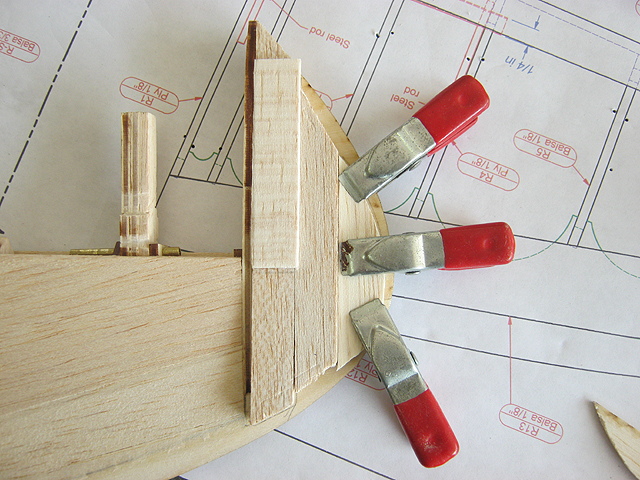

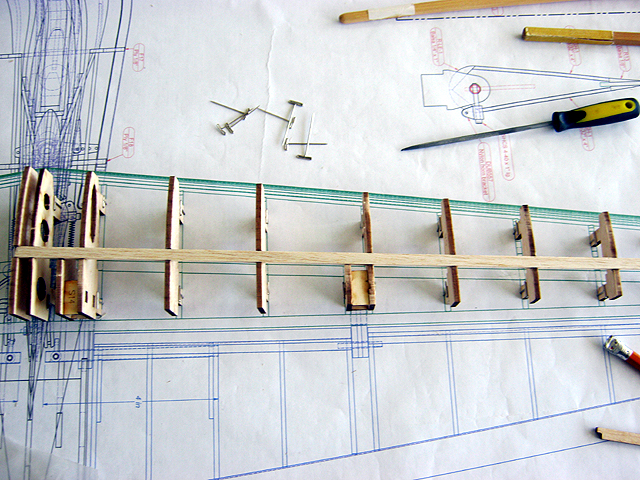

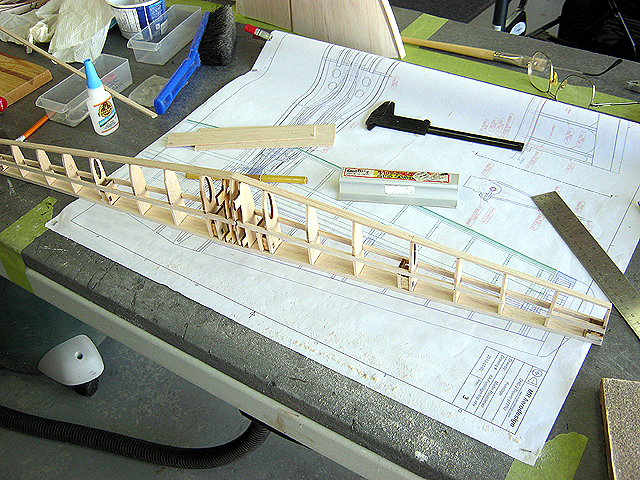

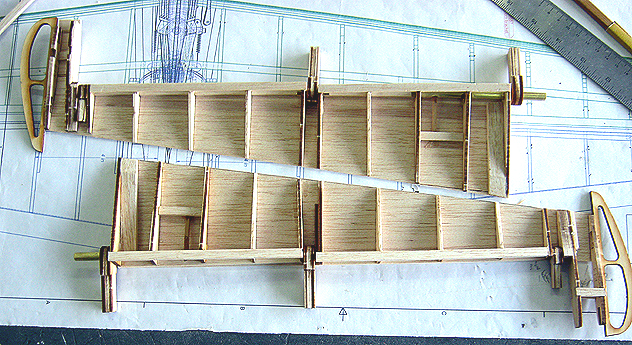

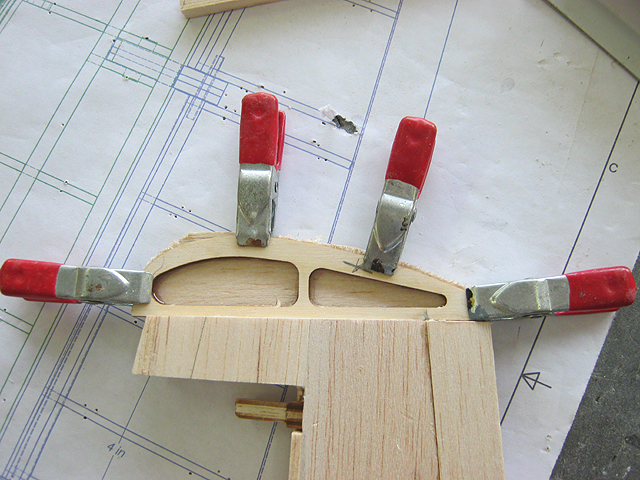

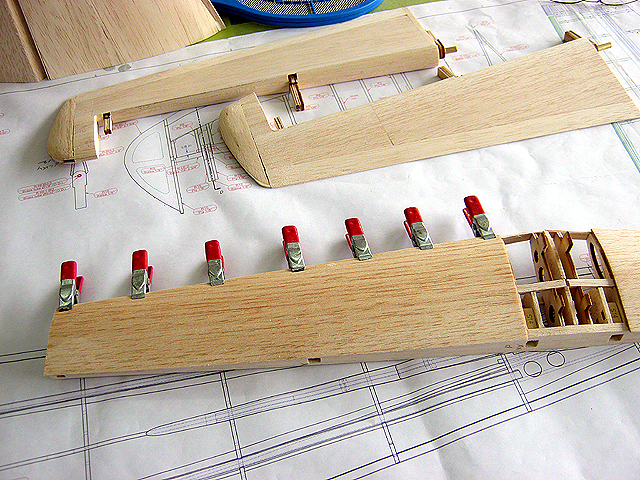

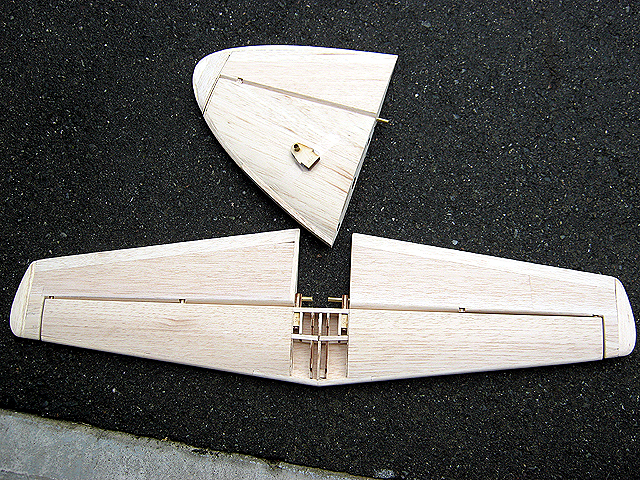

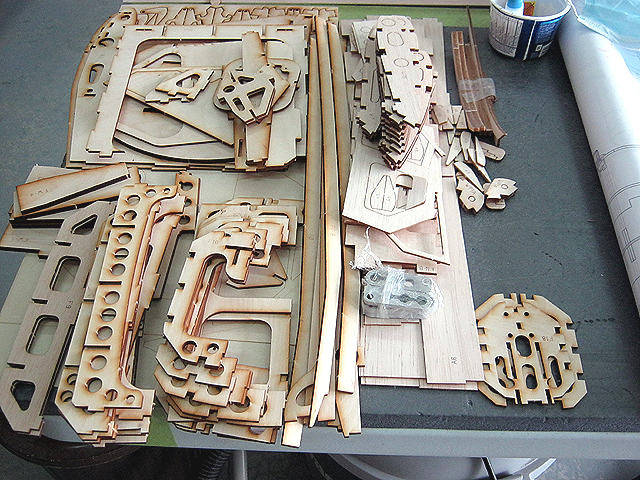

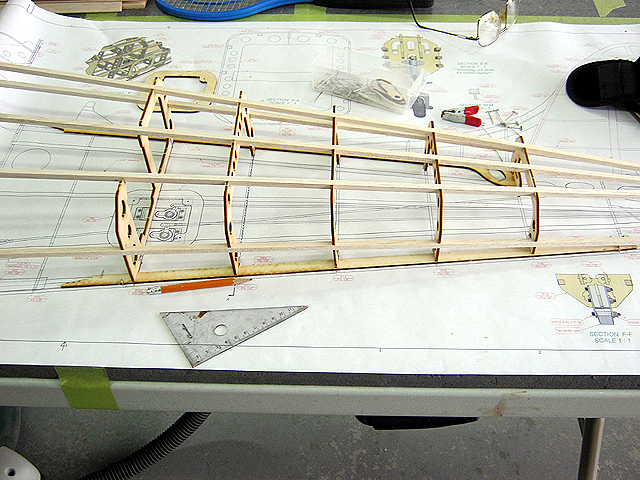

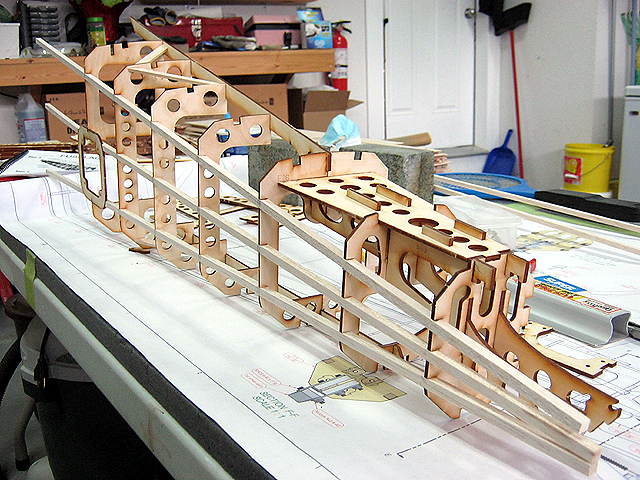

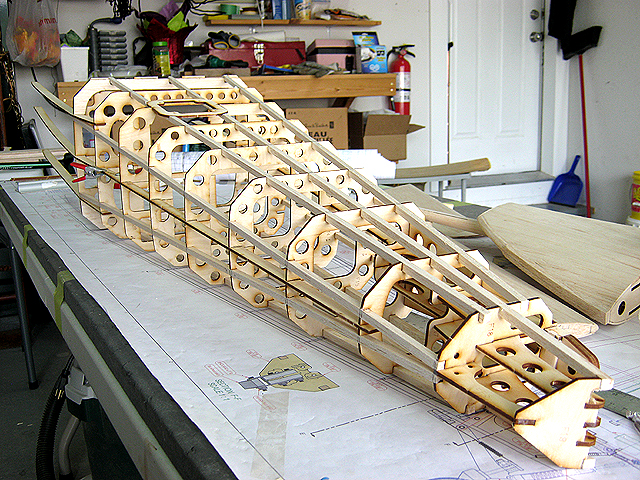

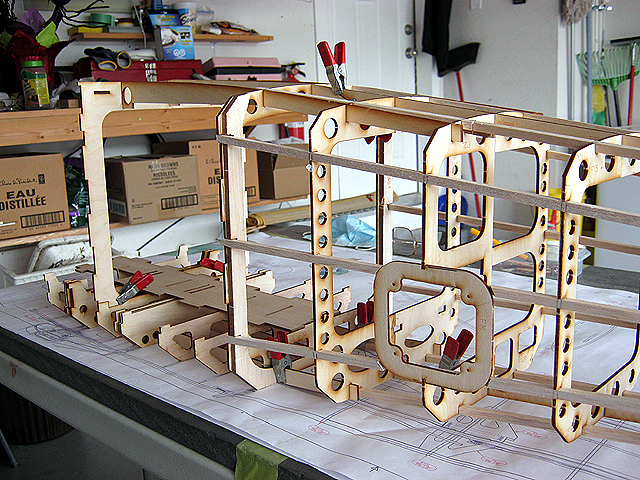

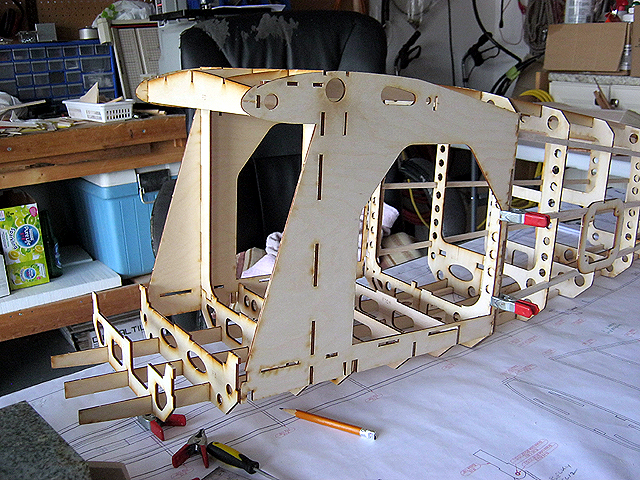

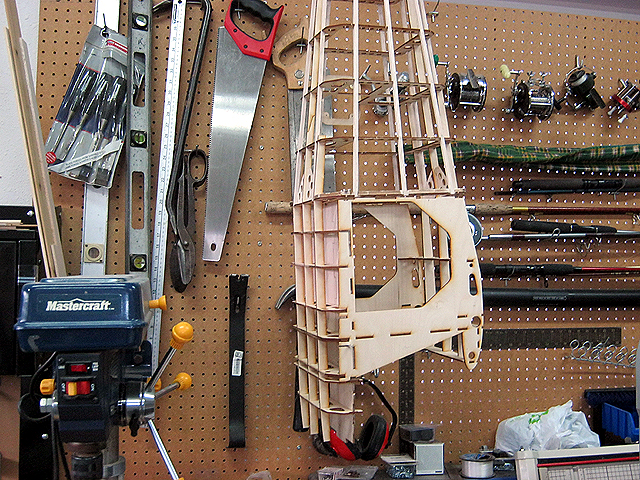

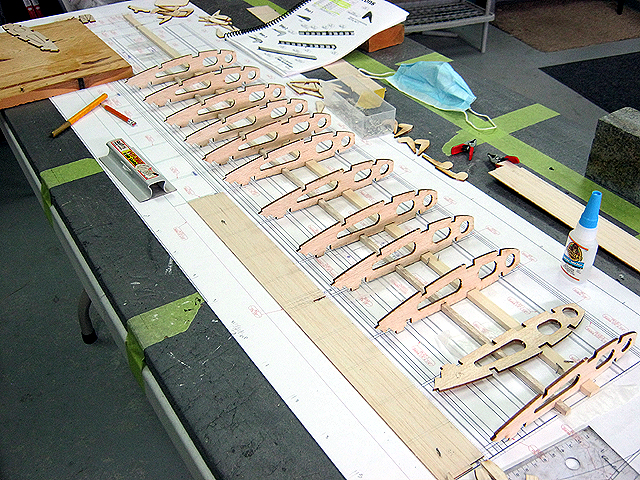

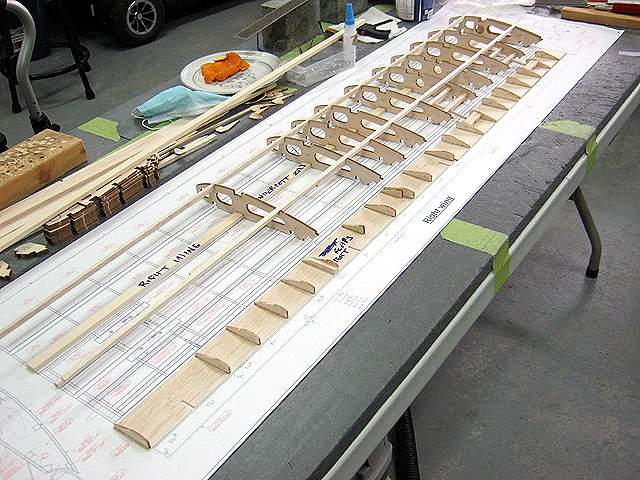

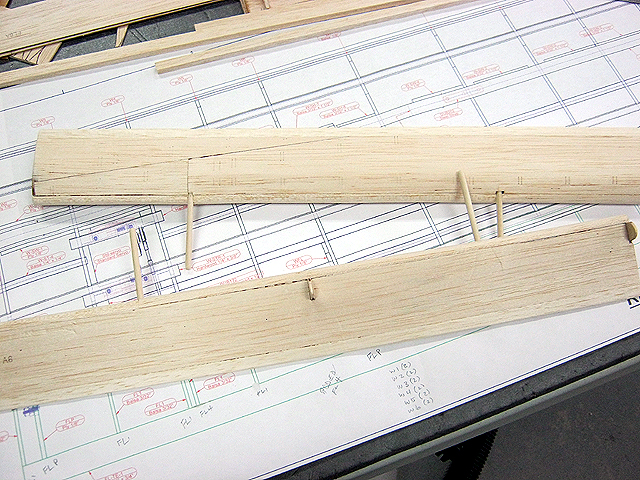

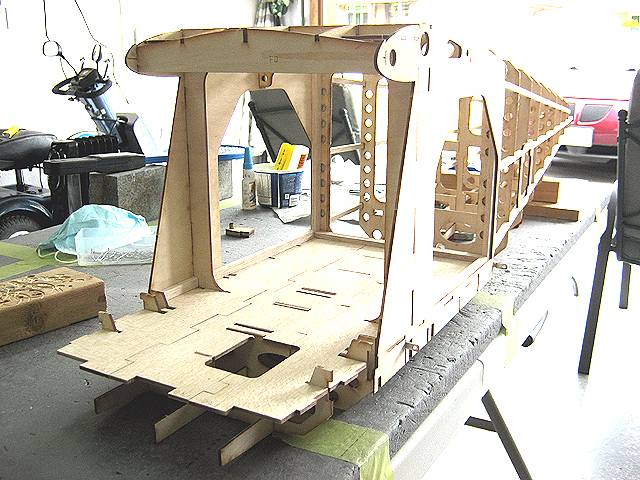

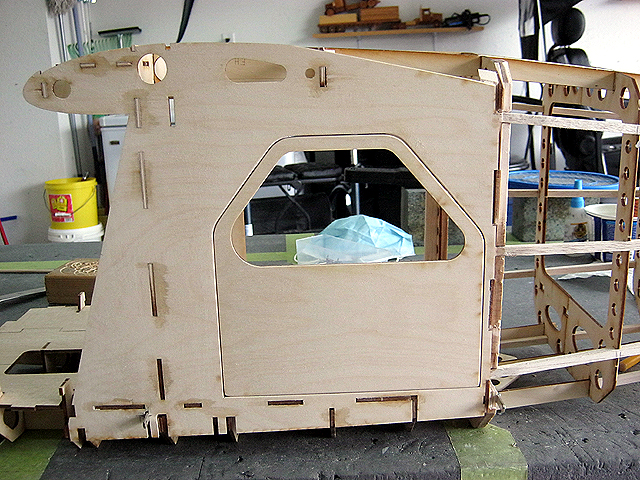

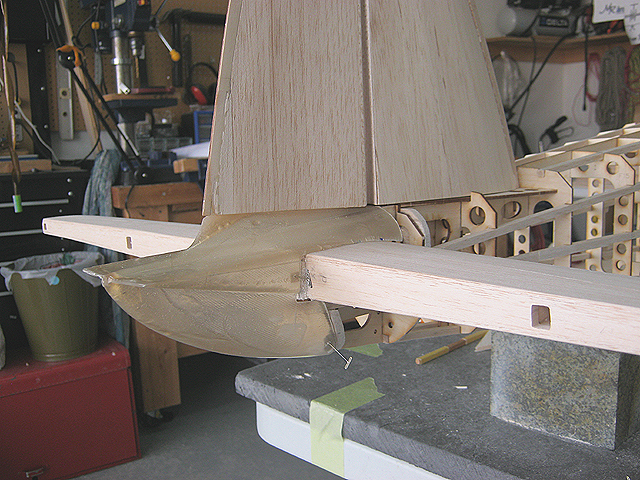

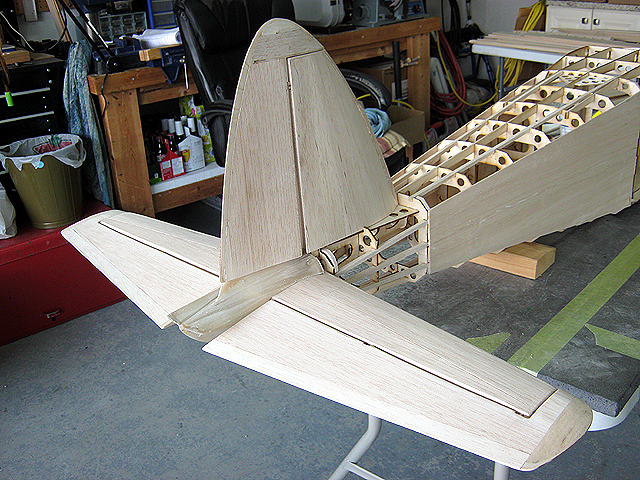

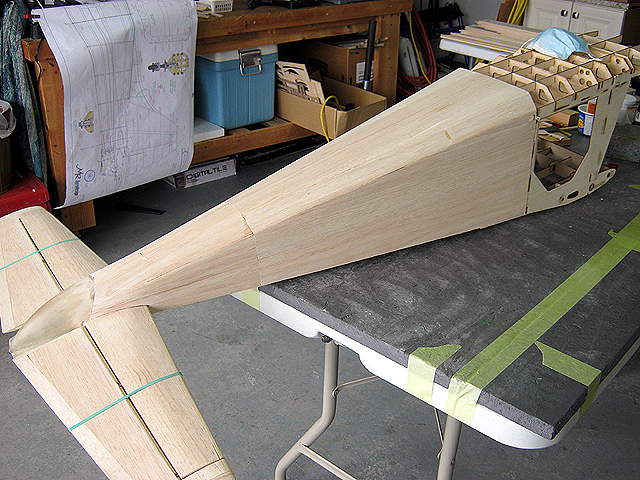

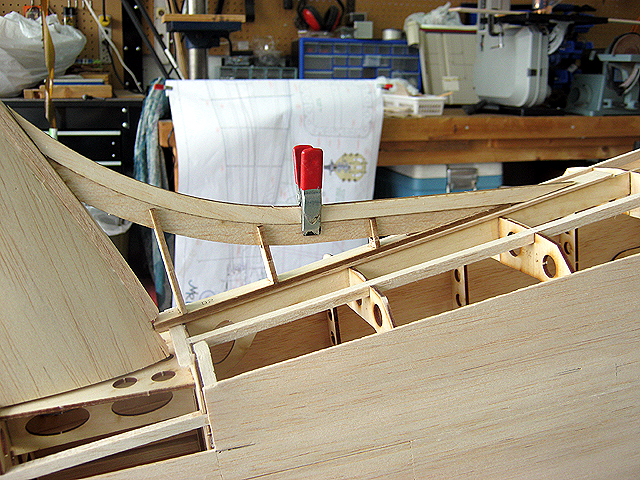

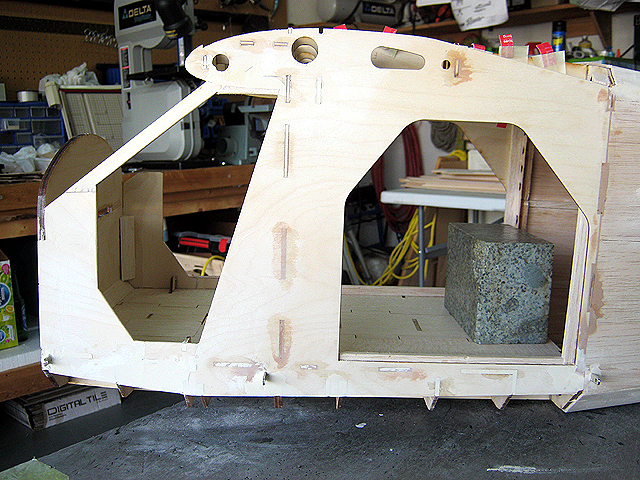

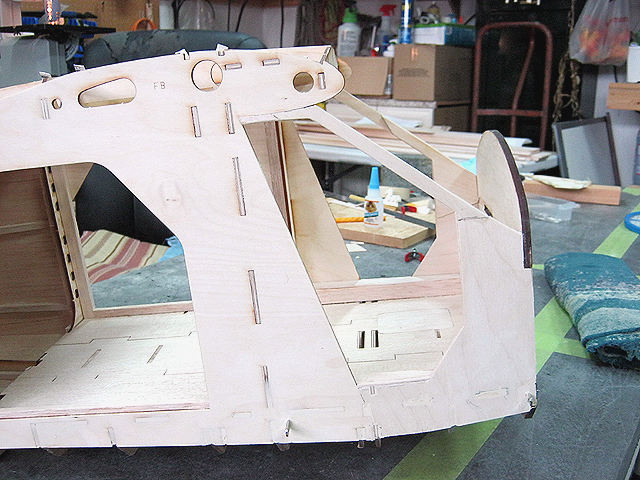

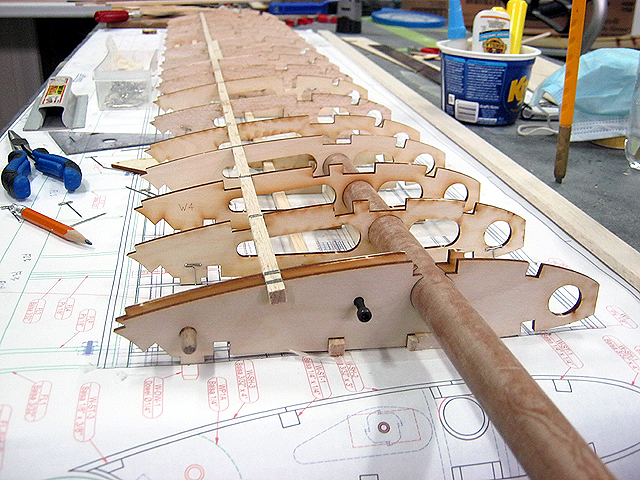

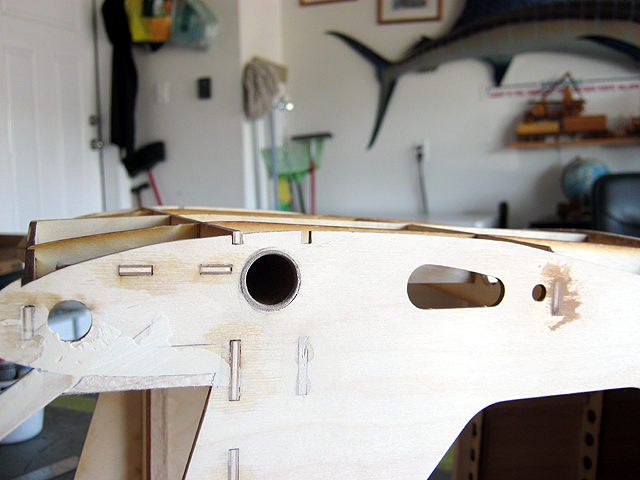

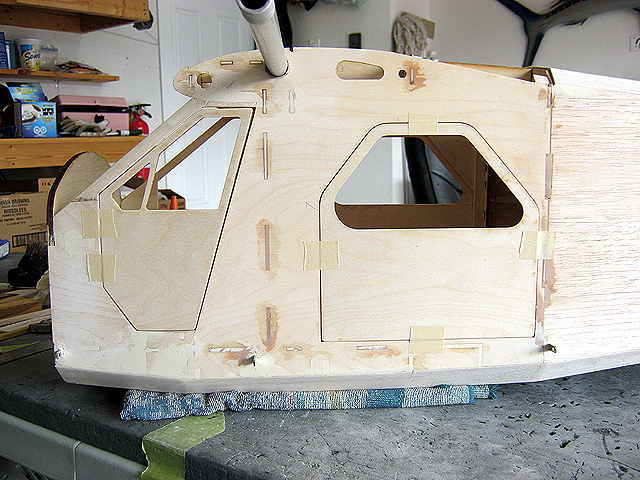

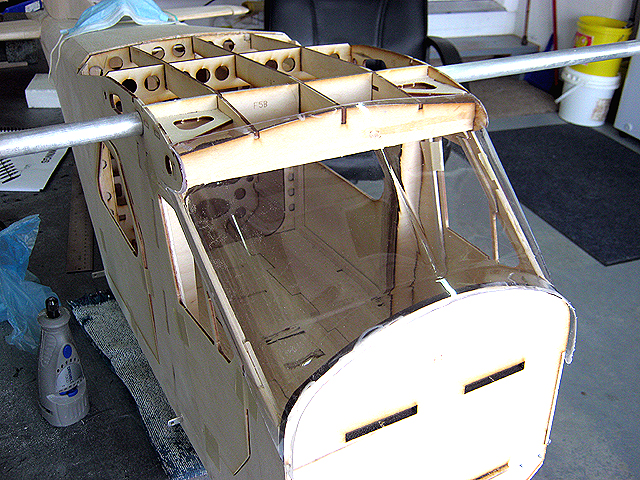

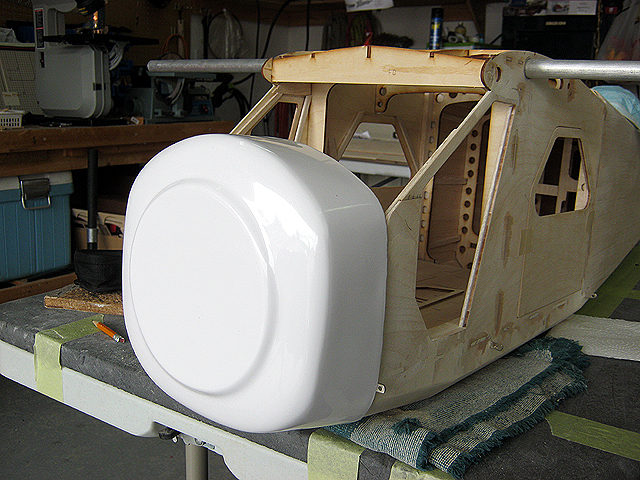

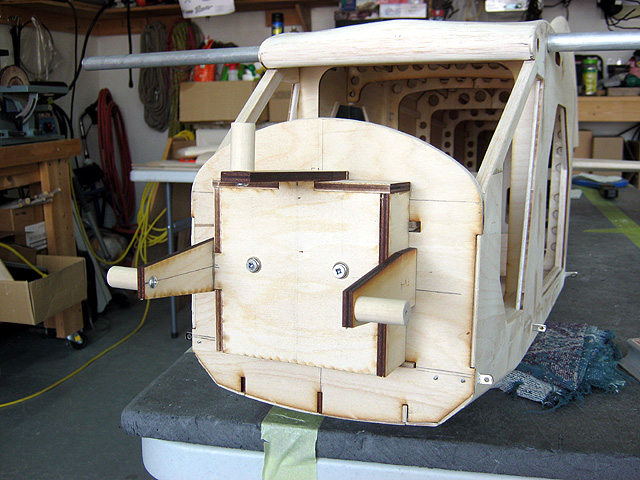

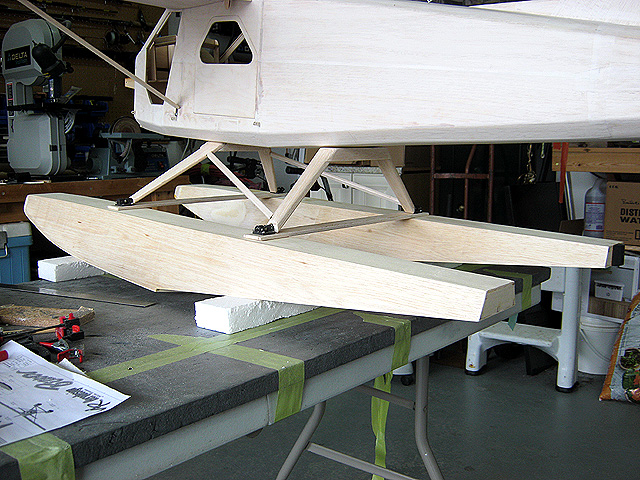

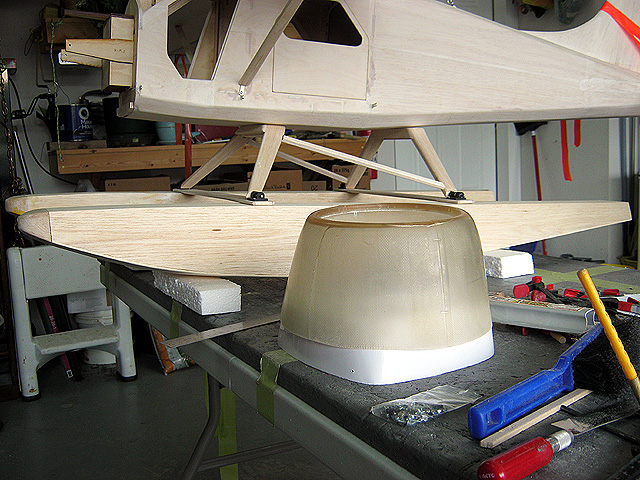

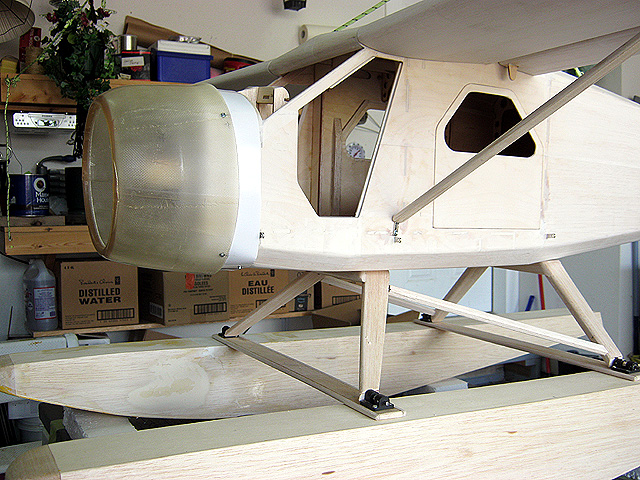

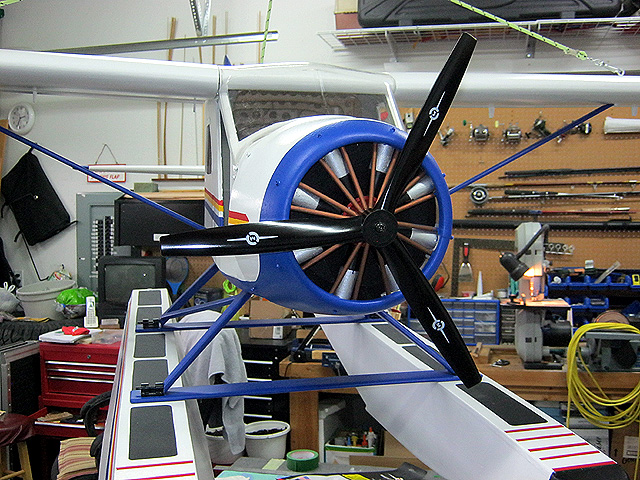

| This build of a quarter scale DeHavilland DHC-2 Beaver on floats with a wing span of 242cm (95") will hang from the ceiling of my workshop. I'm starting with a partial kit from Martin Rousseau, www.mraerodesign.com from Quebec, Canada. I built a Cessna 185 on floats from his catalog. |

|

Webpage design & Maintenance by Alan A Sandercott Terrace B.C. Canada Email: alan@sandercott.ca |